- Yokohama-shi tampam página

- Vivendo, procedimento

- More, enquanto vivendo

- Disposição de lixo / reciclando

- Introdução da facilidade

- Destruição através de fábrica de fogo

- A excursão de fábrica

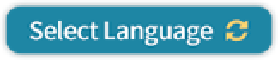

- Waste Incineration Plant Facility Overview

É o texto daqui.

Waste Incineration Plant Facility Overview

Por último atualize data 24 de agosto de 2020

Waste Incineration Plant Facility Overview

Click on the Plant Facility Index to display descriptions and videos of the relevant facilities.

1 plataforma

Garbage trucks dump the waste that they have collected into waste pits from the platform, where it is temporarily stored.

Several hundred garbage trucks drive in and out of the platform every day, and the platform surveillance room monitors the area to ensure that there are no accidents and no unsuitable waste included.

The waste pit doors detect the arrival of the garbage trucks and open automatically.

The garbage trucks raise their rear containers and dump the waste directly into the waste pits from the waste pit doors.

Vehicles with rear containers that cannot be raised have their waste removed manually, although this is carried out safely by first of all transferring it to dumping boxes and then dropping it into the pit down slides to make sure that workers are in no danger of falling into the pit, and it is also at that point that it is possible to prevent unsuitable waste from being dumped if it is discovered.

▲ Click to start the video. (no audio)

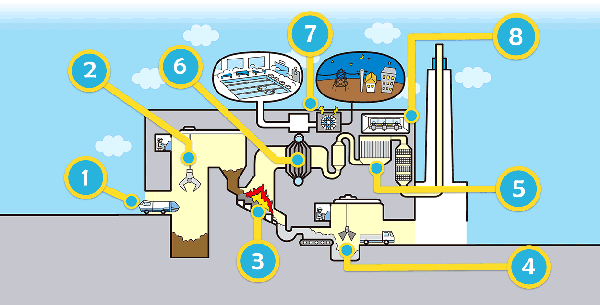

2 Cova de desperdício e Guindaste Desperdício

The area in which the waste transported by garbage trucks is temporarily stored is known as the waste pit.

The waste cranes then pick up the waste and transfer it from the waste pit to the incinerator.

The most important factor at this point is to make sure that the waste is mixed together to make it uniform before it is placed in the incinerator.

Recursos reutilizávéis e substâncias de non-combustível estão cuidadosamente separadas quando é colecionado desperdício para assegurar isso é entregado só desperdício combustível a plantas de incineração como um princípio básico, embora isto inclui que "dificuldade queimou" substâncias, como desperdício de casa com níveis altos de conteúdo de umidade, e "facilmente substâncias queimadas", como papel.

The waste cranes therefore agitate the waste together to make it uniform (with waste agitators) and ensure that it is easily burned.

The waste cranes are operated by qualified operators. Automatic operations are also carried out at nights and at other times when necessary, which means that the cranes are operated ceaselessly on a 24-hour basis.

▲ Click to start the video. (no audio)

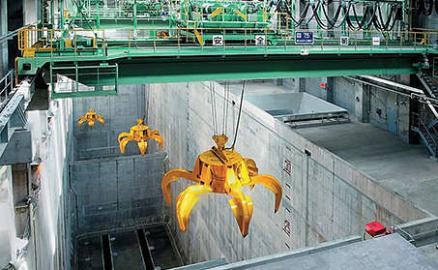

3 incinerador

The waste transferred into the incinerators acts as the fuel for incinerating it. Owing to this, once the incinerator has been started up and ignited, it requires no further fuel until it is shut down.

The incinerators also operate continuously at high temperatures of between 850 and 950 degrees Celsius, which eradicates all odors and cuts down on dioxins.

The air required for incinerating waste is taken in from the waste pit, and the design makes sure that the odors emitted by the waste are not leaked outside.

▲ Click to start the video. (no audio)

4 Cova de cinza e Guindaste de Cinza

The ash pit is where the ash produced during incineration is temporarily stored.

The ash that comes from the incinerator is transferred to the ash pit on an ash conveyor, where it is stored.

The hazardous substances removed by the exhaust-gas treatment facility is also transferred on a different conveyor, treated with chemicals, etc., and each substance stored in the ash pit.

The ash cranes pick up the ash and load it only ash-carrying trucks.

The ash loaded onto these trucks is then transported to the final disposal site.

The final disposal site has limited space, and it is therefore necessary to thoroughly separate the waste to reduce its volume so that the site can be efficiently used for as long as possible

▲ Click to start the video. (no audio)

5 Facilidade de Tratamento de esvaziar-gás

The exhaust-gas treatment facility is where the hazardous substances contained in the exhaust gas emitted during incineration are removed.

First of all, the exhaust gas is rapidly cooled in cooling towers to prevent dioxins from recomposing.The exhaust gas is passed through a device known as the bug filter to remove the fine hazardous substances contained within the gas, and it is then treated with chemicals to remove the dioxins and other hazardous substances.

The hazardous substances that remain in the exhaust gas after this, are then removed with chemicals such as slaked lime, activated carbon and ammonia, etc.

The exhaust gas that has been treated in this way is finally emitted into the atmosphere from the smokestack.

Yokohama City manages exhaust gas at values that are more stringent that those laid down in the regulation standards enforced by law.

We also publicize the results of all measurements into exhaust gas properties, etc., after treatment to provide local residents with peace of mind.

▲ Click to start the video. (no audio)

6 caldeira

Boilers are facilities that boil water with the heat generated during waste incineration in order to produce steam.

The produced steam is sent to steam turbine generators and used for generating electricity.

In addition to using this for air-conditioning and water-heating within the incineration plant, it is also distributed to public use facilities that use residual heat to provide a source of heat for heated pools and public baths.

▲ Click to start the video. (no audio)

7 Gerador de Turbina de vapor

Steam turbine generators are facilities that convert high-temperature, high-pressure steam produced by boilers into electrical energy.

The generated electricity is used within the incineration plant and by public use facilities, and the remainder is then sold to electricity utilities.

It is necessary to improve the combustion efficiency of incineration plants in order to increase the amount of electricity generated by steam turbine generators.

In order to achieve this, Yokohama City requests citizens to wring as much moisture out of household waste as possible, and to make sure that twigs and other foliage pruned from trees and plants are well dried before they are submitted for collection.

▲ Click to start the video. (no audio)

8 Sala de controle central

The waste incineration plant operates ceaselessly on a 24-hour basis.

Because of this, the operators in the Central Control Room oversee the operation and monitoring of the incineration plant 24-hours of every day.

The images taken by cameras installed at various locations throughout the incineration plant are displayed on LCD monitors for surveillance purposes.

The monitors in front of the operators displays temperature, pressure, exhaust gas density and other data in the real time. The on-site equipment is monitored and operated remotely with automatic computer control and manual operations in accordance with the situation to ensure that optimal incineration is being carried out at all times.

▲ Click to start the video. (no audio)

★ Waste Disposal Flow

▲ Click to start the video. (no audio)

Investigação para esta página

Recursos e Agência de Reciclagem de Desperdício processo Planejamento Departamento facilidade seção apropriada

Um telefone: 045-671-2518

Um telefone: 045-671-2518

Fac-símile: 045-664-9490

Um endereço de e-mail: sj-shisetsu@city.yokohama.lg.jp

Chame ID: 813-787-640